ManagedCarePartners

June 6, 2016

Although the Johns Hopkins Health System is still in the midst of a five-year supply chain transformation for which departments systemwide are carefully scrutinizing their supply ordering and usage, it’s already seeing significant financial rewards.

By the end of this fiscal year, the system will see savings of about $50 million, says Ron Werthman, senior vice president and chief financial officer for Johns Hopkins Medicine. “We were targeting anywhere from $80 million to $100 million total, so we’re well on our way to achieving the goal.”

Werthman credits the success to supply chain’s integral relationship with Johns Hopkins’ numerous clinical communities—physician-led groups that aim to improve safety and quality in specific therapeutic areas—and the Armstrong Institute for Patient Safety and Quality.

“In supply chain, without the involvement of the clinicians, we can only influence about 20 percent of the cost,” he says. “We can deal with price. We can’t deal with standardization and utilization — that has to be driven by the physicians. To the extent that the physicians agree to standardize and drive compliance, we can generate substantially greater savings.”

There are three key trends expected to impact health care system viability and patient outcomes in the face of rising supply costs this year, Werthman says: increased collaboration between clinicians and supply chain team members, new approaches to counteracting rising drug prices, and advanced inventory management tactics and tools.

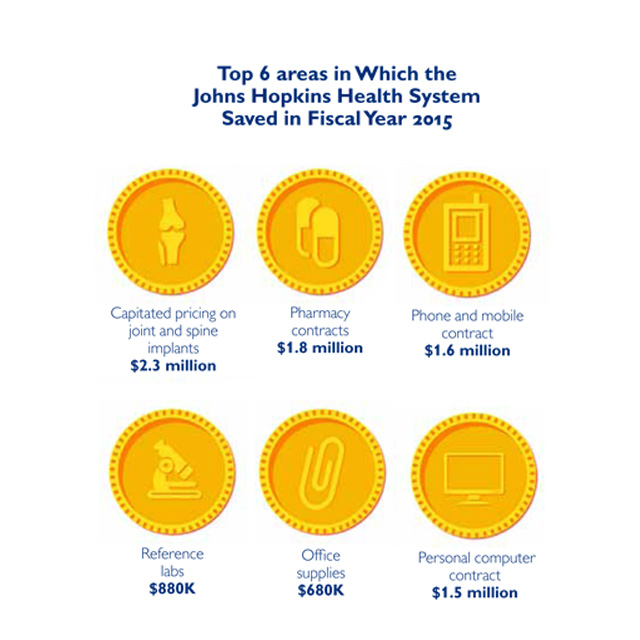

The clinical communities have generated noteworthy savings by analyzing and selecting their preferred medical supplies, such as dialysis catheters; spinal, hip and knee implants; and laryngoscope blades, which helps negotiations for better pricing. For example, the Johns Hopkins Spine Clinical Community, made up of spine surgeons from across the health system, helped the supply chain department achieve $3.3 million in annual spinal surgery savings through value analysis of spinal surgery products used at Johns Hopkins hospitals. Their analysis helped the finance department negotiate down the prices for spinal surgery products by demonstrating to vendors their products’ value to Johns Hopkins.

To counteract rising drug prices, pharmacists have been establishing protocols to encourage or require the use of therapeutic equivalents to drugs whose prices have skyrocketed in recent years. One for The Johns Hopkins Hospital states that 11 drugs, including intravenous acetaminophen (whose cost rose from $10 a dose to over $40 between 2014 and 2016), should only be administered intravenously when certain conditions are present, such as a patient’s inability to swallow. Otherwise, less costly oral-administered medications of equal effectiveness should be used.

There’s also a movement to make prescription drug prices more accessible to clinicians so they’ll better understand the financial impact of their prescribing. In 2015, prescription drug price information was added to a Johns Hopkins Health System database of referential information about drugs in the formularies of all five Baltimore-area Johns Hopkins hospitals.

In inventory management, the health system is making good use of electronic supply management and ordering software systems. All six Johns Hopkins Health System hospitals conduct inventory management functions through business software. This supports the integration of stockrooms systemwide, making it possible for different departments to share items that otherwise might go to waste. The hospital pharmacies are also joining the trend, tracking supplies used, wasted or about to become obsolete, and adjusting their ordering routines accordingly. And in March, Johns Hopkins All Children’s Hospital debuted touch-screen hand-held devices to scan supplies and enter counts in the system via an on-screen keyboard to increase the accuracy of inventory data.